We clean your air-cooled heat exchangers to increase unit throughput, reduce energy and sour water rates, and prevent unnecessary CapEx projects

ReNu Technologies' clients see the difference.

“My unit area is on regularly scheduled cleanings with [ReNu] every October and will continue to do so. Their process has alleviated a lot of maintenance on belts, motors, and bearings in the fin fan components. They’re also very easy to work with from an operations perspective.”— Coker Maintenance Manager, Texas Refinery

ReNu Technologies' clients see the difference.

“I had an issue with my ARU fin fans. In the past, another company had used chemistry that created decay on the fins due to electrolysis… As we were having cooling constraints, I needed assistance quickly … [ReNu] prescribed a very low-pressure solution so as not to knock off any more fins than had already come dislodged. Not only did their Nucleated Foam work, but they were also able to save my fan deck and create more cooling capacity that yielded an additional $1.0MM in additional production annually.”— ARU Process Engineer, Texas Refinery

ReNu Technologies' clients see the difference.

“I had just cleaned my Hydrocracker unit 11 days prior to meeting [ReNu]. I’d told him, the unit had just been cleaned by a competitor. He believed there was more cooling capacity to be had … Upon completion, they expanded the temperature delta and daily increases which yielded between $6,600.00 and $7,150.00/day in output production. Ever since meeting [ReNu] that day, I only use [ReNu] for my fin fan cleaning.”— Hydrocracker Process Engineer, California Refinery

ReNu Technologies' clients see the difference.

“We’ve deployed [ReNu] on sitewide cleanings … Even though they’d cleaned individual units in the past and did an amazing job, we were still surprised to see a 5.0x+ ROI — and that did not include utility or water conservation calculations for the revenue side … Additionally, their technology and process allowed us to remove this process from our TAR entirely.”— TAR Superintendent, Illinois Refinery

ReNu Technologies' clients see the difference.

“I was responsible for coordinating 2/3 (about 350 fans) of our refinery fan cleanings using [ReNu]. I can say, they have been the easiest company to work with. They communicate and execute with operations better than any other contractor in this space that I’ve experienced. Our operators love 'em and their results were exactly as they described them to be.”— Routine Maintenance Superintendent, Texas Refinery

ReNu Technologies' clients see the difference.

“Other providers said they could do what [ReNu] was claiming, but they simply didn’t deliver. We first tried the Nucleated Foam on our crude unit fans — which had just been cleaned 30 days prior. Not only were their lines of communications excellent, but they also delivered on all their claims. In the economic reporting, we were able to establish more than $2.3MM in additional output capacity with only having 14 fans cleaned. This additional revenue (on just these fans) was enough to pay for an entire site wide of our facility.”— Crude Process Engineer, Minnesota Refinery

ReNu Technologies' clients see the difference.

“I’ve never experienced a better job at fin fan cleaning in the 8.5 years I’ve been here than what you guys provide.”— Crude Area Business Team Lead, Texas Refinery

ReNu Technologies' clients see the difference.

“[ReNu] has been integral in our record-breaking production levels. We use their Nucleated Foam plant wide annually.”— Refinery Manager, Indiana Refinery

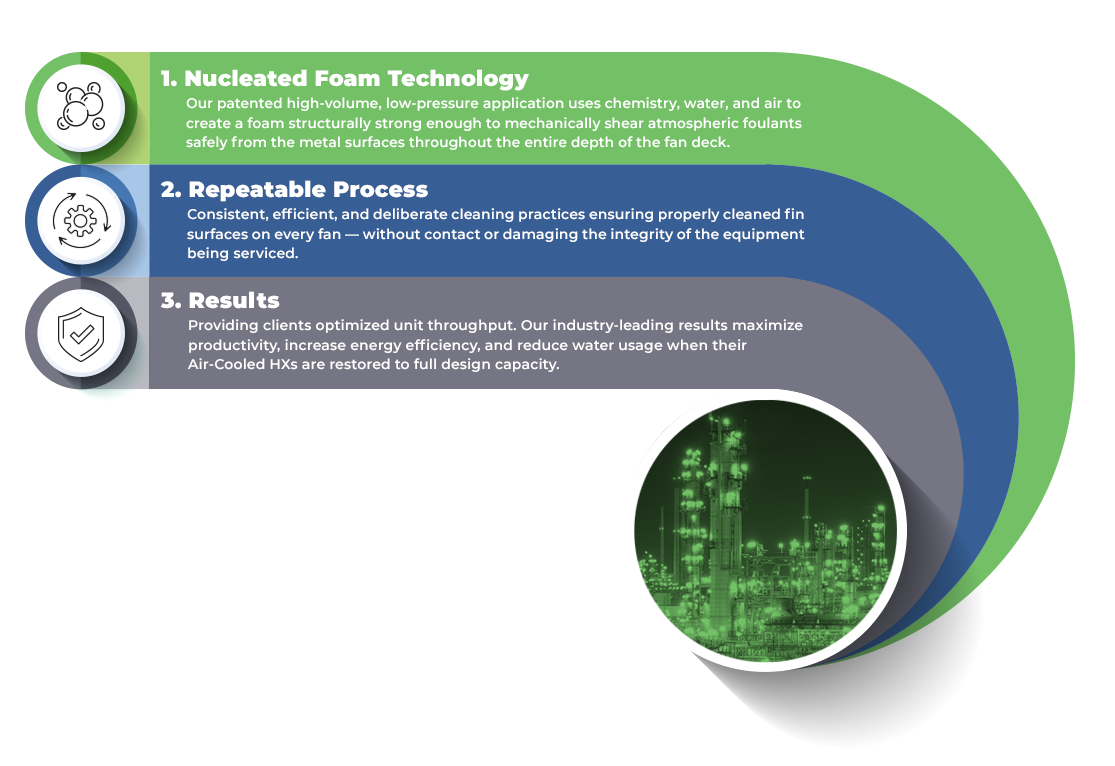

Our globally patented Nucleated Foam Technology and its repeatable process removes OD atmospheric foulants that cause cooling constraints and limit production to Air-Cooled Heat Exchangers and returns them back to “as-designed” air flow capacities.

The combination of our patented Nucleated Foam Technology and repeatable processes ensures all atmospheric foulants are removed, while the unit remains online.

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.

Benefits include:

- Repeatedly proven site-wide cleaning

- As designed full production airflow capacities

- 360° foulant encapsulation and removal ensures full-fin surface cleaning

- Full foulant extraction through all layers of coils

- No thermal shock — tested up to 740°F

- No production loss during cleaning as processes remain online

- Scaffold/crane manhours go to zero in 95% of all deployments

- Client ESG profile enhancement — newly expanded cooling capacity sometimes allows for fan shutdown post clean. Energy savings can be in the thousands per month.

- Extreme ease for Maintenance and Operations

- Measurable metrics for proven value

- No Lock-Out, Tag Out (LOTO)

- Safe across all metallurgies

- Environmentally and ecologically safe

Nucleated Foam

Technology Benefits

ReNu’s Technology and Analytics delivers exceptional ROI

ReNu Technologies Total Fan Health is designed to maximize our clients' return on investment (ROI). All ReNu Technology projects are focused on delivering professional service with exceptional results that translate to client production, throughput, and energy efficiency gains. Validated results and analytical data are documented and shared, providing real value statements post project along with clear justification for future projects and budgets. It is not enough to just increase cooling capacity, we work to identify and lift production and energy constraints.

ReNu Technologies’ SDS — Environmental and Ecological Conservation

- ReNu Technologies is committed to safe environmental and ecological practices. We take pride in knowing our Nucleated Foam Technology does not endanger the environment nor any of the sensitive surrounding ecosystems.

SDS as Delivered:

- Dilution safe, neutral pH

- Extremely high dilution ratios

- Safe for wastewater treatment facilities

- Foulants are atmospheric (outside of vessel) such as pollen, dust/dirt, sand, cottonwood fluff, mayflies, salt, etc.

- A percentage of effluent liquids evaporate just as on a rainy day and are safe to remain in ground and or go to sewer

- Environmentally proven in highly restrictive water ecological/conservation regulations, such as the Puget Sound, coastal California, and Mississippi River basins and deltas

- Concentrations well below LC50 specifications

About ReNu Technologies

ReNu Technologies combines RTI’s industry expertise and AeroCore’s patented technology to bring Total Fan Health to every facility experiencing cooling constraints limiting production. ReNu’s focus is to optimize our client’s unit throughputs, energy, and water usage by keeping their facility air-cooled heat exchangers clean and operating at full design capacity throughout the year.

Serving Others First

At ReNu Technologies, we value ethics and integrity in every aspect of our operations. We dedicate ourselves to protecting our people and the environments we serve while fostering a culture of growth, recognition, and rewarding high performance. These core principles guide us as we strive to be a responsible and respected leader in the industries we serve.

Leaving An Impact

ReNu Technologies’ vision is to expand the use of our patented Nucleated Foam Technology and be a leader in aiding in production, efficiency, and sustainability opportunities within the markets we serve. We will accomplish this by leveraging both physical and digital tools to unlock real value for our clients.

Our Mission

HONOR GOD ALWAYS

This looks like fulfilling commitments as promised, delivering outstanding work products, being respectful and kind to everyone, protecting rhythms of work and rest, and wisely stewarding our resources.

HELP PEOPLE DEVELOP

ReNu is committed to nurturing the growth of all team members as they continue to learn and help us reach our business objectives.

PURSUE EXCELLENCE

Setting the bar high, we provide unparalleled service and achieve superior results. We are inspired by delivering exceptional results every time, everywhere.

EARN A PROFIT

While most companies set out to make a profit, we are intentional about our aim to earn a profit by ensuring that we are creating value for our clients that exceeds the fee that we charge.